|

|

|

By 1956 Christner’s business flourished extremely well until Dieter Konig sent over some of his racing engines which were equipped with megaphones. Those engines gave Christner’s motors quite a run for the money. Up to that time O.F. had not experimented with or used any type of exhaust tuning like the Konig engines had that gave them more power. Remember the only measure of power was to test the engine on a boat or in a water tank. Between 1957 and 1963 the Kongs were becoming so competitive that unless O.F. did something they would be effectively out of the racing business in spite of the fact that the four cylinder C&D Mercs were very reliable and reasonable in cost. So, Christner started experimenting with megaphones on the Mercs, which increased the power and kept them competitive. These engines became known as “Quincy Mercs” or Merc Quincy’s” which were the forerunner of the Quincy “Loop” engines. O.F. says, “Of course we had enough success during those years to attract the attention of the “Perfect Circle” Corporation known worldwide for their engine parts; particularly piston rings.”

|

|

At Christner’s shop in Quincy, Illinois the greater part of the time spent by his 12 employees is revamping Mercurys for racing. He was usually modifying 30 to 40 engines and one time on an assembly line basis and at one time had customers in all 50 states as well as Japan, Germany, Austria, Africa, England and Argentina. This assembly line included inserting and welding pads, machining pistons, prop reworking, enlarging ports, timing engines, installing pump impellers, welding exhaust megaphones to headers, among other duties. O.F. had several patents on his piston/exhaust header designs and said “we would increase the compression ratio by welding inserts into the cylinders head and breathing ability by enlarging the intake ports.” This was done because of the fuel conversion to alcohol among other things, and the high RPM’s of the engine would not hold the head together which was under extreme pressure. In regard to fuel conversion from gasoline to “alky” blend, O.F. used one quart of castor oil to five gallons of methanol. O.F. designed and made his own pistons, machining the entire surface to the piston to precise measurements. O.F. says, “There are basically two types of pistons - cross flow and loop scavenge. At first, in the cross flow engines we built up the piston tops wit heliarc and machined the shape that worked best. Eventually we had a piston manufacturer make the pistons, with surplus material everywhere, and then machine them to exact shape.” It was interesting to note that O.F. specified a one ring piston to accommodate a chrome plated ring. “With chrome rings we can run all season,” he said, adding, “a chrome ring seems to go ten times as far as a cast iron ring.”

|

|

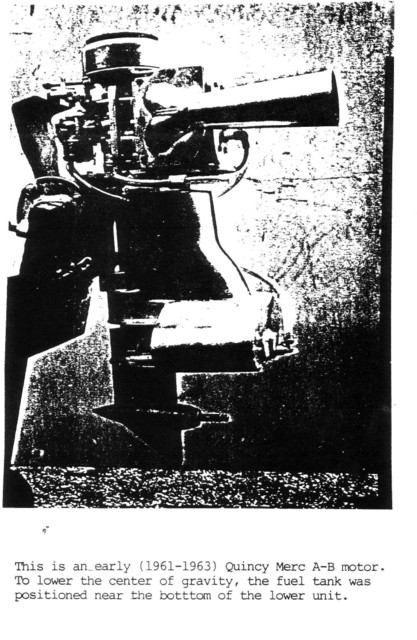

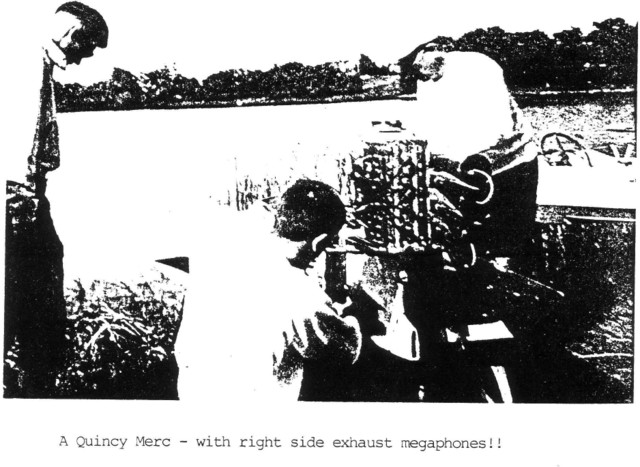

Another Christner innovation was the tuned exhaust pipes, which converge the exhaust of the two alternate firing cylinders into a single megaphone. O.F. says, “this also increases the engine’s breathing ability and power output. The acceleration is terrific.” Christner also re-designed the fuel tank to provide a lower center of gravity. Propellers get much attention and one specialist had a full time job increasing the accuracy of their pitch on dies devised by Christner. Props were and still are designed to the weight of the driver and boat as well as the length of the course and water conditions. “Changing a prop on an outboard matches the quick-change rear-end on racing cars.” Some of his employees at the time were highly successful in various classes of runabouts and hydroplanes and competed in APBA as well as NOA sanctioned events. O.F. also designed a special trailer which carried seven racing boats at one time as well as an assortment of modified engines, props, tools, helmets and all the necessary parts to meet any emergency.

“When publicity given to us by Perfect Circle Corporation got on E.C. Keikhaufer’s desk at the Mercury factory he was very unhappy.” said O.F. He (Kiekhaefer) said, “The factory puts power in Merc engines,” and as a direct result, cancelled the franchise which would put Quincy Welding and Marine out of business. At that time, O.F. recalls, “we were using about $15,000 worth of Merc parts each month and it probably took all the persuasive powers of Charles Strang who was with Mercury at that time, and who is now CEO of Outboard Marine Corporation, to get Mr. Kiekhaufer to give Christner back his franchise. If it wasn’t for this effort everything would be lost.

|

|

The period between 1957 and 1963 was made even more difficult when a good friend of Christner’s, W.L. Tenney, a famous racer himself at the time, brought over from England, an Anzani racing engine which were in O.F.’s words, “Tougher to compete with than Konig’s.” I have been told, however, that the Anzani engine was too heavy and the weight restriction ultimately kept them from becoming a major factor in outboard racing. Both the Konig and Anzani engines used slightly crowned pistons which would tolerate a lot more heat than the cross-flow “deflector” pistons that were required in the Mercs and while O.F. knew how to get more air in the engine, the pistons simply would not tolerate more heat as the deflector would burn off, thus destroying the engine. More on this later, but here O.F. talks about his competition.

“During those years we had many competitors, one of which was Larry Rodgers who at the time was working for Champion Motors.” In the 50's Champion outboard engines made serious inroads into the competitive records of Mercury as well as other manufacturers engines that were competing at the time. “Freddie Goehl who was driving for me at the time, couldn’t quite catch Larry but my son David Christner could handle him somehow. It was good competition.” 1962 was a sad year as two of his best drivers, Freddie Goehl and Arlin Crouch left and went into competition with Christner in Byron, Texas. But after a while they found out that there wasn’t all that much money in this type of work and evolution is the key word in racing as we all know. Evolution and innovation, I might add.

|

|

Almost every year O.F. and his family went to Florida for Christmas vacation and coming home one year he conceived the idea of putting two cylinders into one megaphone, which was described earlier, to increase acceleration and he thought the Konig B engine couldn’t do this because their exhaust came out of both sides of the motor. The advantage that O.F. had then didn’t last very long because Walt Blankenstein of Konig simply rotated one cylinder 180 degrees and copied Christner’s design very quickly.

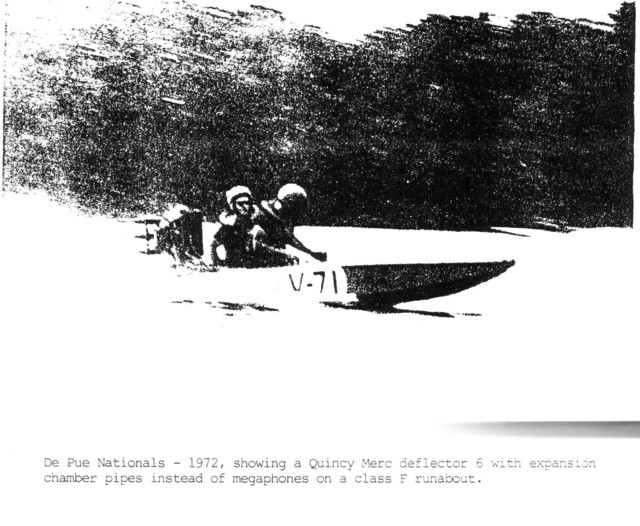

Early in 1963, Christner took his rigs to a race in the South where he knew his ex-employees Arlin Crouch and Freddie Goehl would also be racing, hoping to surprise them with the “two into one” pipe innovation, but they already had this set up supplied to them by another Christner employee!! O.F. was not happy about it. He also realized at this time that it was obvious that the days of the deflector pistons in racing engines were over so he went to work by putting flat-top pistons in the Mercs. Deflector pistons are used in cross-flow engines. Their purpose was to deflect the incoming gasses upwards in the cylinder for scavenying. Because they have such a high surface area exposed to the combustion gasses, they only work in low power uses, that is where O.F. started with the early cross-flow Mercs. But as power increased, the deflector top usually about ½ inch high, would melt off and the engine would barely run. In 1964 he acquired a full scale dynamoniter which helped in engine test tremendously.

|

|

Because of the nature of loop scavenge piston ports, the Merc crankshaft throws were too close together to conventionally work properly. O.F. had to devise a way to do this somehow. Therein the Quincy “Looper” was born. The exhaust came out of both sides of the cylinder, a first in a two-cycle engine. This design was very successful and kept him in racing for the next seven to eight years. O.F. was not the first to build a loop scavenge engine. A man by the name of Schnurle was the very first and his patents ran out 30+ year ago. Most engine builders used the loop scavenging method as it allowed a flat top piston to be used and it would tolerate a lot mor heat and power than the cross-flow engines that had a deflector on top of the piston to prevent the fresh charge from going out the exhaust ports which were directly across from the inlet ports. O.F. was the very first to use this system on pure production cross-flow engines and no one had done so since. “Because the cylinder bores were so close together you could not use the standard Schnurle system so we devised the merging of exhaust streams right in the engine. This method should permit high RPM’s which we never really took advantage of.” he says. E.C. Keikaefer liked the design according to Christner, since no one ever did before. It was with these “Looper” engines that Jerry Waldman won every conceivable outboard class in its time.

|

|

In 1971 Jerry took the National Championships in A-C-D-F “alky” hydro to become the first and only four class national title winner in history. In fact says Charles Strang, “he also won C Service Section II to make it five titles.” Jerry won at least 45 national championships, 26 APBA titles and 19 NOA titles!! In ensuing years he held at one time or another every competition record in stock and alky racing hydro class. In 1965 he held all of the NOA competition and kilo records in the alky hydro classes at the same time! These were done with the Quincy “Looper” racing engines converted from Mercs.

After 1971 O.F. says, “The blasted foreigners were giving us trouble again.” At that time he was working for Mercury on Lake X on a special assignment and left his employees in charge

of the shop to work on racing engines. Not much improvement occurred between 1971-1975 so being finished with the assignment for Mercury he returned to Quincy from Florida to see if he could keep up with the advancing technology of the Japanese and German racing engines which had government funding. He could get the power but the Merc 20-H crankshaft could not hold above a 8500 RPM’s. It became necessary to use a much heavier crankshaft and to do so meant redesigning the entire engine. O.F. says, “In doing so we decided to go to the modular cylinders which made possible one, two three or more cylinders to fit various displacement classes.” O.F.’s youngest son, Paul, who had been around racing all his life was following older son David and getting into the action and the old saying “two heads are better than one” was sure true. What O.F. couldn’t remember, Paul could. So the first engine they developed was a “B” that ran very well in as much as it was a two cylinder running against the four cylinder German engines. Paul ran it at Winona, Minnesota which was the first race he ran in and did well as he had the most power there, but in the back of the pack as he was instructed to by O.F. With modular cylinders O.F. constructed the 125cc single engines that still hold most of the records in “M” class. Then he constructed a three cylinder “C” that got 125 horsepower.

At this time O.F. says, “I made a ‘boo-boo’ and decided to use water injection with the exhaust system instead of tuned sliding pipes like the foreign race engines.” The mechanics were too difficult for most people to master. In 1984 he sold the racing business to Jack Kugler of Great Lakes Boat Company who is continuing to manufacture Quincy racing engines, which continue to set speed records.

|

|

Now retired in Florida he misses the ongoing development work and sense of competition he had during his years in business. When I contacted him, he asked to gratefully acknowledge those who helped him in this article: E.C. Kiekhaefer, Charles Strang, Edgar Rose, Bob Johnson, Charles Alexander, Jack Leek, Jim Schoch, Earl Hull, Bob La Lande, J.H. Donley, Gene East, Leroy Kelley, Rich Weisenberger, Al Herman, Michael Malaney. Other acknowledgements to remember are: Jerry Wienandt, David Christner, Tom Mueller, Steve Warnoch, Larry Latta, Karl Williams, Henry Franck, and Mercury Performance Products. Also, Paul Christner and W. Claude Fox, executive director of National Outboard Association.

|

|

|