|

|

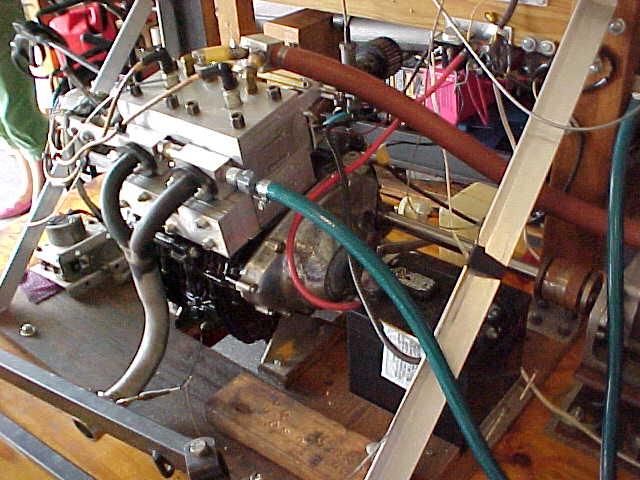

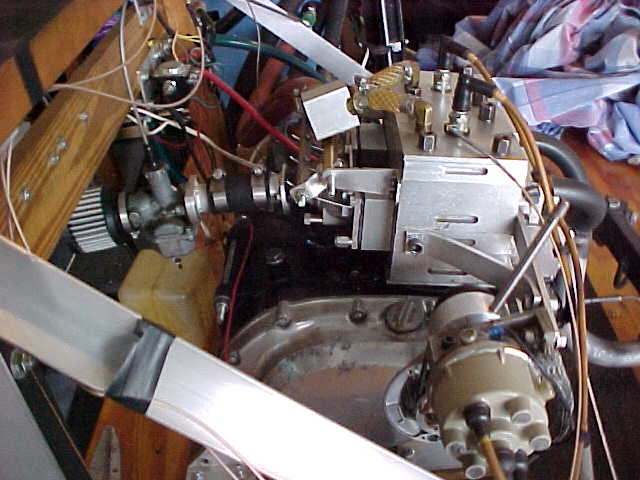

Experimental 2-4 Cycle Engine

|

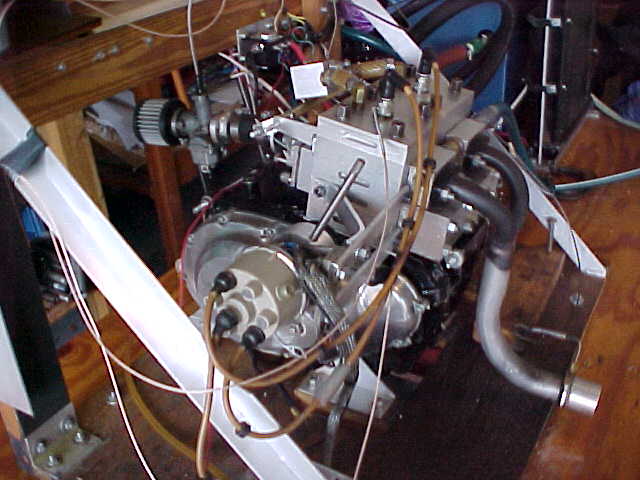

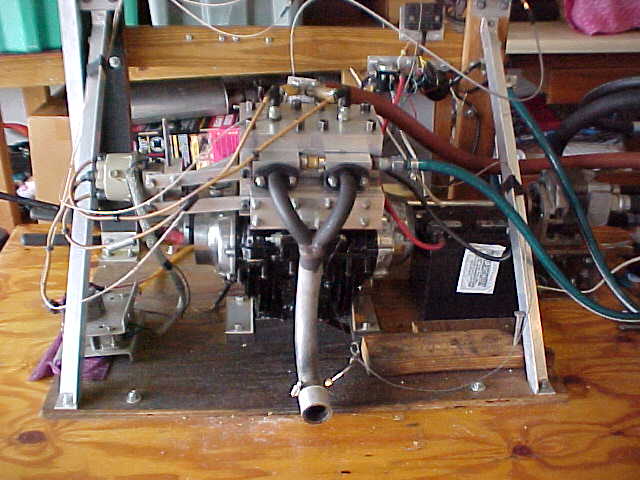

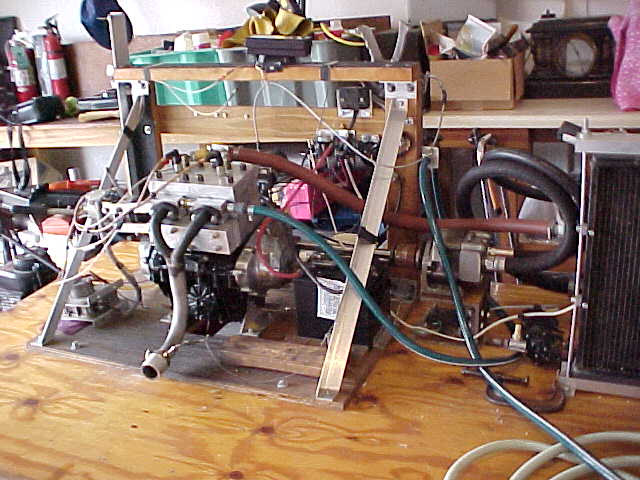

You are seeing for the very 1st time, exclusive pictures of the experimental 2 - 4 cycle Christner engine. This engine was engineered and developed by O. F. and Paul Christner, based on the last patent filed by my father (and brother David). I was heavily involved with this project from the very first pencil drawings all the way to this first phase, prototype engine as seen in the pictures.

|

Concept

|

The concept behind this engine is my father's dream of having the simplicity of a 2 cycle motor integrated with the durability and fuel efficiency of a 4 cycle motor that doesn't need oil mixed with the gas to operate. This working prototype is that dream realized.

|

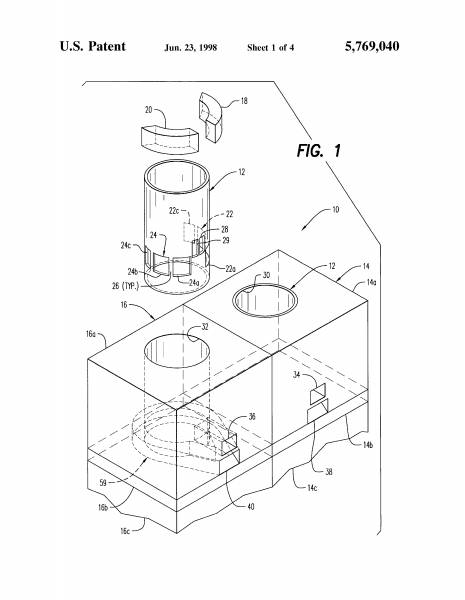

If you would like to pull up the patent on this engine concept so you can better understand the inner workings of this engine design, it is US Patent # 5,769,040.

Here is a link to the patent:

http://www.google.com/patents?vid=USPAT5769040&id=N24mAAAAEBAJ&dq=5,769,040

Application

|

My father and I thought the best application for this engine would be in a hybrid type car or other transportation vehicle, something like the Toyota Prius. In other words, having a highly efficient and simplistic designed engine for the purpose of generating power to an electric vehicle while achieving extremely low emissions, cost, service, etc.

|

Abstract from Patent

|

ABSTRACT FROM PATENT:

An improved two cycle internal combustion engine, preferably of a stepped piston type, having a unique arcuately shaped transfer deflector valve, which varies by its controlled sliding movement within an inlet passage, the size of exposed opening of an elongated inlet port in the cylinder. The inlet port extends circumferentially part way around the cylinder. The leading end of the valve is preferably angled, in cooperation with the preferably almost tangent orientation of the inlet passage, to induce arcuate movement into each fresh full charge entering the combustion chamber for enhanced fuel charge mixing. In the preferred embodiment, two such valves are symmetrically positioned around the cylinder and arcuately move in unison between closed and open positions over corresponding opposing inlet ports.

(Patent number: 5769040,

Filing date: Apr 18, 1997;

Issue date: Jun 23, 1998)

|

What is Claimed

|

What is claimed is:

1. An inlet system for a two cycle internal combustion engine comprising: a cylinder and a piston which slidably translates within said cylinder and defining a combustion chamber between a closed end of said cylinder and a head of said piston; (see part 2)

|

What is Claimed (part 2)

| |

a wall of said cylinder including at least two inlet ports therethrough extending substantially circumferentially part way around said cylinder and in fluid communication with an inlet passage; an elongated arcuately shaped transfer deflector valve mounted for sliding arcuate movement within said inlet passage which, when closed, is in substantial alignment with at least one said inlet port, an inner arcuate surface of said transfer deflector valve substantially sealingly engaged against a portion of an outer surface of said cylinder wall adjacent at least one said inlet port; said transfer deflector valve sized and slidably movable between a closed position wherein at least a substantial portion of at least one of said inlet port is covered by said transfer deflector valve and an open position wherein substantially all of at least one said inlet port is open and uncovered by said transfer deflector valve; means for controlledly positioning said transfer deflector valve at any point between said closed and said open position whereby said inlet ports are sequentially opened in proportion to movement of said transfer deflector valve.

|

What is Claimed (part 3)

| |

2. An inlet system for a two cycle stepped piston internal combustion engine comprising: first and second cylinders positioned in spaced side by side relation and adapted for alternate firing, said first and second cylinders each having a smaller diameter combustion section and a larger diameter pumping section; a stepped piston for each said cylinder including a power section in substantially sealed sliding contact within said combustion section of said cylinder and a pumping section in substantially sealed sliding contact within said pumping section of said cylinder; a wall of each said combustion section of each said cylinder including at least two inlet ports therethrough extending circumferentially part way therearound in fluid communication with an inlet passage;

an elongated arcuately shaped transfer deflector valve mounted for sliding arcuate movement within each said inlet passage in substantial alignment with at least one corresponding said inlet port, an inner arcuate surface of each said transfer deflector valve substantially sealingly engaged against a portion of an outer surface of said cylinder wall adjacent at least one said inlet port;

each said transfer deflector valve sized and slidably moveable between a closed position wherein at least a substantial portion of at least one corresponding said inlet port is covered by one said transfer deflector valve and an open position wherein substantially all of each said inlet port is open and uncovered by said transfer deflector valve;

means for controlledly positioning each said transfer deflector valve anywhere between said closed and said open position; two transfer passages each in fluid communication between said pumping section of said cylinder and a corresponding said inlet passage of said cylinder whereby a fresh fuel charge drawn into each said pumping section during each downstroke of a corresponding said piston and is forced into said inlet passage of said cylinder during each upstroke of the corresponding said piston.

3. An inlet system for a two cycle internal combustion engine as set forth in claim 1, wherein: a leading end of said transfer deflector valve is angled in cooperation with said inlet passage whereby each fresh fuel charge entering said inlet passage is deflected into said combustion chamber having an arcuate movement for enhanced fuel mixture uniformity just prior to combustion.

|

4. An Inlet System.....

|

4. An inlet system for a two cycle internal combustion engine as set forth in claim 1, further comprising: a second transfer deflector valve having a substantially mirror image shape of said transfer deflector valve and symmetrically positioned in opposing fashion with respect to said transfer deflector valve for sliding arcuate movement within a portion of a second inlet passage which is in substantial alignment and fluid communication with a second elongated inlet port formed through said wall of said cylinder;

|

4. An Inlet System....(part 2)

| |

said second inlet port being symmetric in size and positioning with respect to said inlet port, said second transfer deflector valve being slidably moveable between said closed and said open position with respect to said second inlet port;

means for controlledly positioning said second transfer deflector valve at any point between said open and said closed position simultaneously with that of said transfer deflector valve.

|

5. An Inlet System....

| |

5. An inlet system for a two cycle internal combustion engine comprising: a cylinder and a piston which slidably translates within said cylinder and defining a combustion chamber between a closed end of said cylinder and a head of said piston;

a wall of said cylinder having at least two inlet ports therethrough extending substantially circumferentially part way around said cylinder through less than about 180.degree. and in fluid communication with an inlet passage;

an elongated arcuately shaped valve means for sliding arcuate movement within said inlet passage which en closed is in substantial alignment with at least one said inlet port, an inner arcuate surface of said valve means being substantially sealingly engaged against a portion of an outer surface of said cylinder wall adjacent at least one said inlet port;

means for controlledly positioning said valve means at any point between a closed position wherein at least a substantial portion of at least one said inlet port is covered by said valve means and said open position wherein substantially all of at least one said inlet port is open and uncovered by said valve means.

|

6. An Inlet System.....

| |

6. An inlet system for a two cycle internal combustion engine as set forth in claim 2, wherein:

a leading end of each said transfer deflector valve is angled in cooperation with each said inlet passage whereby each fresh fuel charge entering each said inlet passage is deflected into said combustion chamber having an arcuate movement for enhanced fuel mixture uniformity just prior to combustion.

|

7. An Inlet System....

|

7. An inlet system for a two cycle internal combustion engine as set forth in claim 2, further comprising:

a second transfer deflector valve having a substantially mirror image shape of said transfer deflector valve and symmetrically positioned in opposing fashion with respect to said transfer deflector valve for sliding arcuate movement within a portion of a second inlet passage which is in substantial alignment and fluid communication with a second elongated inlet port formed through said wall of said cylinder;

|

7. An Inlet System.....(part 2)

| |

said second inlet port being symmetric in size and positioning with respect to said inlet port, said second transfer deflector valve being slidably moveable between said closed and said open position with respect to said second inlet port;

means for controlledly positioning said second transfer deflector valve at any point between said open and said closed position simultaneously with that of said transfer deflector valve.

|

8. An Inlet System...

| |

8. An inlet system for a two cycle internal combustion engine as set forth in claim 5, wherein:

a leading end of said transfer deflector valve is angled in cooperation with said inlet passage whereby each fresh fuel charge entering said inlet passage is deflected into said combustion chamber having an arcuate movement for enhanced fuel mixture uniformity just prior to combustion.

|

9. An Inlet System....

| |

9. An inlet system for a two cycle internal combustion engine as set forth in claim 5, further comprising:

a second transfer deflector valve having a substantially mirror image shape of said transfer deflector valve and symmetrically positioned in opposing fashion with respect to said transfer deflector valve for sliding arcuate movement within a portion of a second inlet passage which is in substantial alignment and fluid communication with a second elongated inlet port formed through said wall of said cylinder;

said second inlet port being symmetric in size and positioning with respect to said inlet port, said second transfer deflector valve being slidably moveable between said closed and said open position with respect to said second inlet port;

means for controlledly positioning said second transfer deflector valve at any point between said open and said closed position simultaneously with that of said transfer deflector valve.

|

10. An Inlet System....

| |

10. An inlet system for a two cycle internal combustion engine comprising:

a cylinder and a piston which slidably translates within said cylinder and defining a combustion chamber between a closed end of said cylinder and a head of said piston;

a wall of said cylinder including at least two inlet ports therethrough extending substantially circumferentially part way around said cylinder and in fluid communication with an inlet passage;

arcuately shaped transfer deflector valve mounted for sliding arcuate movement within said inlet passage which, when closed, is in substantial alignment with at least one said inlet port, an inner arcuate surface of said transfer deflector valve substantially sealingly engaged against a portion of an outer surface of said cylinder wall adjacent at least one said inlet port;

said transfer deflector valve sized and slidably movable between a closed position wherein at least a substantial portion of at least one said inlet port is covered by said transfer deflector valve and an open position wherein substantially all of at least one said inlet port is open and uncovered by said transfer deflector valve;

means for controllediy positioning said transfer deflector valve at any point between said closed and said open position whereby said inlet ports are sequentially opened in proportion to movement of said transfer deflector valve.

|

11. An Inlet System...

| |

11. An inlet system for a two cycle stepped piston internal combustion engine comprising:

first and second cylinders positioned in spaced side by side relation and adapted for alternate firing, said first and second cylinders each having a smaller diameter combustion section and a larger diameter pumping section;

a stepped piston for each said cylinder including a power section in substantially sealed sliding contact within said combustion section of said cylinder and a pumping section in substantially sealed sliding contact within said pumping section of said cylinder;

a wall of each said combustion section of each said cylinder including at least two inlet ports therethrough extending circumferentially part way therearound in fluid communication with an inlet passage;

an arcuately shaped transfer deflector valve mounted for sliding arcuate movement within each said inlet passage in substantial alignment with at least one corresponding said inlet port, an inner arcuate substantially continuous surface of each said transfer deflector valve substantially sealingly engaged against a portion of an outer surface of said cylinder wall adjacent said inlet port;

each said transfer deflector valve sized and slidably moveable between a closed position wherein at least a substantial portion of at least one corresponding said inlet port is covered by one said transfer deflector valve and an open position wherein substantially all of each said inlet port is open and uncovered by said transfer deflector valve;

means for controlledly positioning each said transfer deflector valve anywhere between said closed and said open position whereby said inlet port is sequentially opened in proportion to movement of said transfer deflector valve;

two transfer passages each in fluid communication between said pumping section of said cylinder and a corresponding said inlet passage of said cylinder whereby a fresh fuel charge drawn into each said pumping section during each downstroke of a corresponding said piston and is forced into said inlet passage of said cylinder during each upstroke of the corresponding said piston.

|

12. An Inlet System...

| |

12. An inlet system for a two cycle internal combustion engine comprising:

a cylinder and a piston which slidably translates within said cylinder and defining a combustion chamber between a closed end of said cylinder and a head of said piston;

a wall of said cylinder having at least two inlet ports therethrough extending substantially circumferentially part way around said cylinder through less than about 180.degree. and in fluid communication with an inlet passage;

an elongated arcuately shaped valve means for sliding arcuate movement within said inlet passage which, when closed, is in substantial alignment with said inlet port, an inner arcuate substantially continuous surface of said valve means being substantially sealingly engaged against a portion of an outer surface of said cylinder wall adjacent said inlet port;

means for controlledly positioning said valve means at any point between a closed position wherein at least a substantial portion of said inlet port is covered by said valve means and said open position wherein substantially all of said inlet port is open and uncovered by said valve means.

|

13. An Inlet System...

| |

13. An inlet system for a two cycle internal combustion engine comprising:

a cylinder and a piston which slidably translates within said cylinder and defining a combustion chamber between a closed end of said cylinder an a head of said piston;

a wall of said cylinder including an elongated inlet port therethrough extending substantially circurnferencially part way around said cylinder and in fluid communication with an inlet passage;

said inlet port including end wall segments which are angled in cooperation with said inlet passage to arcuately deflect each fresh charge of fuel entering said inlet passage into said combustion chamber for enhanced full mixture uniformity just prior to combustion;

an elongated arcuately shaped transfer deflector valve mounted for sliding arcuate movement within said inlet passage which, when closed, is in substantial alignment with said inlet port, an inner arcuate substantially continuous surface of said transfer deflector valve substantially sealingly engaged against a portion of an outer surface of said cylinder wall adjacent said inlet port;

said transfer deflector valve sized and slidably movable between a closed position wherein at least a substantial portion of said inlet port is covered by said transfer deflector valve and an open position wherein substantially all of said inlet port is open and uncovered by said transfer deflector valve;

means for controlledly positioning said transfer deflector valve at any point between said closed and said open position whereby said inlet port is sequentially opened in proportion to movement of said transfer deflector valve.

|

14. An Inlet System....

| |

14. An inlet system for a two cycle stepped piston internal combustion engine comprising:

first and second cylinders positioned in spaced side by side relation and adapted for alternate firing, said first and second cylinders each having a smaller diameter combustion section and a larger diameter pumping section;

a stepped piston for each said cylinder including a power section in substantially sealed sliding contact within said combustion section of said cylinder and a pumping section in substantially sealed sliding contact within said pumping section of said cylinder;

a wall of each said combustion section of each said cylinder including an elongated inlet port therethrough extending circumferentially part way therearound in fluid communication with an inlet passage;

each said inlet port including end wall segments which are angled in cooperation with said inlet passage to arcuately deflect each fresh charge of fuel entering said inlet passage into said combustion chamber for enhanced full mixture uniformity just prior to combustion;

an elongated arcuately shaped transfer deflector valve mounted for sliding arcuate movement within each said inlet passage in substantial alignment with a corresponding said inlet port, an inner arcuate surface of each said transfer deflector valve substantially sealingly engaged against a portion of an outer surface of said cylinder wall adjacent said inlet port;

each said transfer deflector valve sized and slidably movable between a closed position wherein at least a substantial portion of each said inlet port is covered by one said transfer deflector valve and an open position wherein substantially all of each said inlet port is open and uncovered by said transfer deflector valve;

means for controlledly positioning each said transfer deflector valve anywhere between said closed and said open position whereby said inlet port is sequentially opened in proportion to movement of said transfer deflector valve;

two transfer passages each in fluid communication between said pumping section of said cylinder and a corresponding said inlet passage of said cylinder whereby a fresh fuel charge drawn into each said pumping section during each downstroke of a corresponding said piston and is forced into said inlet passage of said cylinder during each upstroke of the corresponding said piston.

|

15. An Inlet System....

| |

15. An inlet system for a two cycle internal combustion engine comprising:

a cylinder and a piston which slidably translates within said cylinder and defining a combustion chamber between a closed end of said cylinder and a heat of said piston;

a wall of said cylinder having an elongated inlet port therethrough extending substantially circumferentially part way around said cylinder through about less that 18020 and in fluid communication with an inlet passage;

said inlet port including end wall segments which are angled in cooperation with said inlet passage to arcuately deflect each fresh charge of fuel entering said inlet passage into said combustion chamber for enhanced full mixture uniformity just prior to combustion;

an elongated arcuately shaped valve means for sliding arcuate movement within said inlet passage which, when closed, is in substantial alignment with said inlet port, an inner arcuate surface of said valve means being substantially sealingly engaged against a portion of an outer surface of said cylinder wall adjacent said inlet port;

means for controlledly positioning said valve means at any point between a closed position wherein at least a substantial portion of said inlet port is covered by said valve means and said open position wherein substantially all of said inlet port is open and uncovered by said valve means.

|

|

|