|

|

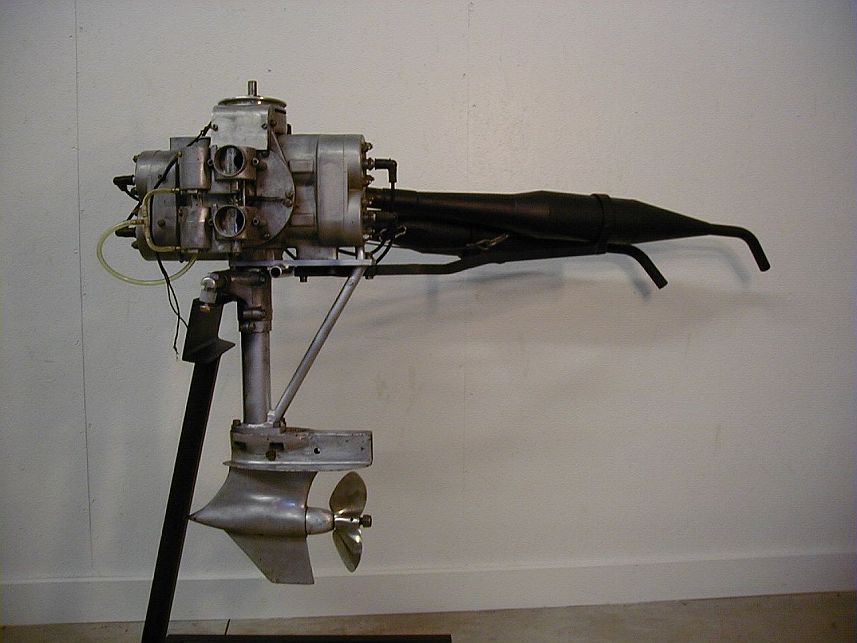

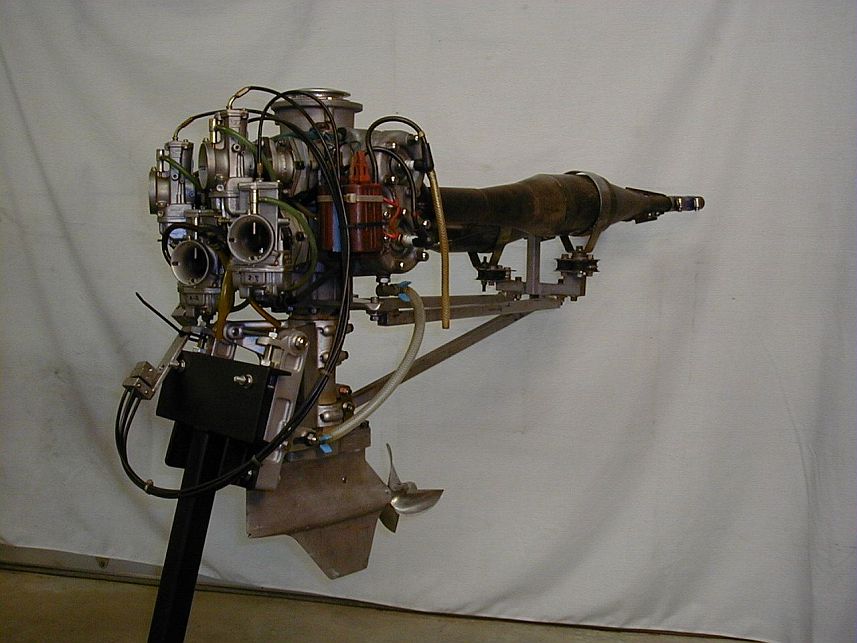

1967 Konig Rotary Valve Model VC

|

1967 Konig Rotary Valve Model VC

The four cylinder rotary valve racing motor design was a real break-through for Konig in terms of speed capability. A family of four displacements was initially produced to cover A, B, C and D alky racing classes with a minimal number of motor differences (largely just bore sizes). This motor is an example of the class C version. It is a loop-scavenged flat opposed engine with the cylinders facing fore and aft. A flat-plate rotary valve is on the port side of the crankcase with one carburetor for each pair of cylinders. The rotary valve is driven through a cogged belt by a gear on the top of the crankshaft and two pulleys that alter the belt direction by 90 degrees. Exhaust exits on the starboard side of the engine through a sliding expansion chamber for each pair of cylinders. The powerhead is on a stick tower with the conventional Konig “tee” bar boat mount system and tubular steering bar. The lower unit is the typical early style design with no water pump… coolant circulation is induced by forward motion of the motor with a water pick-up on the nose of the lower unit gearcase. This motor is equipped with a 15:16 LU gear ratio.

This particular motor was raced by Bloise Williams of Savannah, Georgia.

|

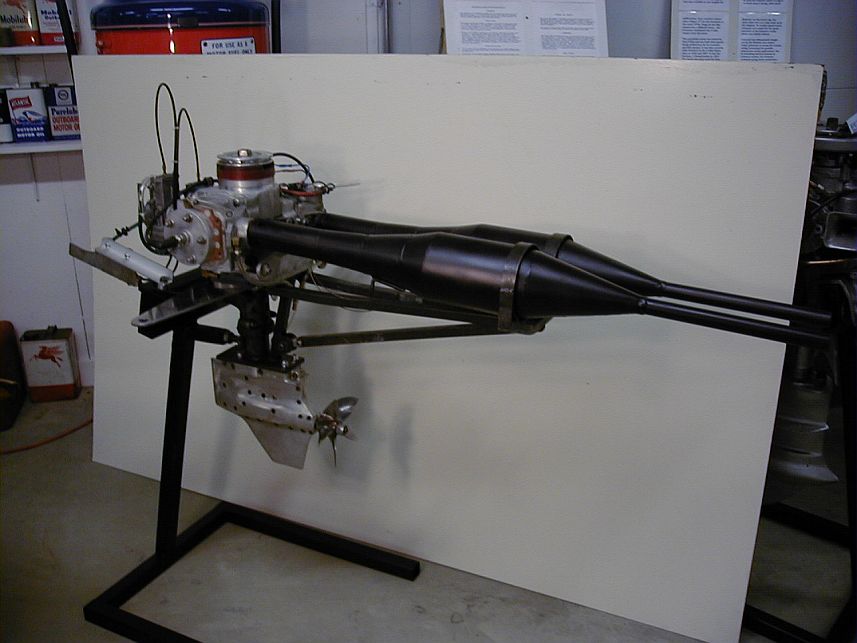

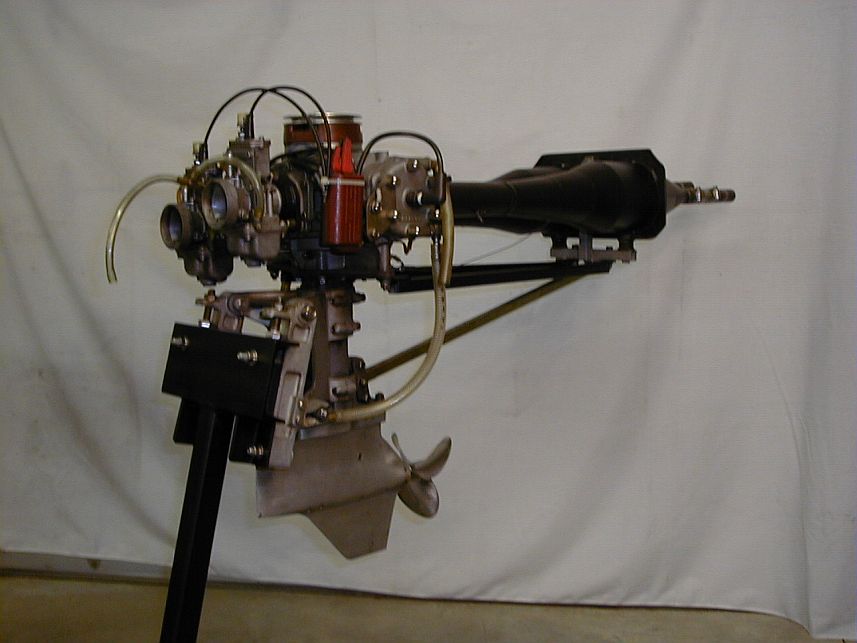

1967 Konig Rotary Valve Model VC (2)

|

2nd photo

|

1929 Lockwood Model 92 BR Racing Chief

|

1929 Lockwood Model 92BR Racing Chief

This motor was essentially designed by Finn Irgens, Lockwood’s Chief Engineer. It is an evolution of the standard Lockwood Chief model. The major differences from the Chief included dual carburetors with a progressive linkage and distinctive air horns, smaller flywheel (same as that used on the Lockwood “Ace” and fitted with a tach-drive flywheel nut), drip oilers for supplying additional lubricant to the upper and lower main bearings and a unique Chinese red cylindrical fuel tank for ease of recognizability. Although Lockwood had high hopes for this motor winning a lot of races, the use of sleeve bearings and the “bulbous” looking conventional lower unit made the engine easy prey for the 1929 Johnson SR racing motor. Although the factory recommended use of an extremely rich oil:fuel mix in addition to the supplemental lubing of the main bearings, the Racing Chief was still prone to bearing failures when subjected to sustained high speed wide-open-throttle operation (this particular motor was found with a large hole in the side of the crankcase where one of the connecting rods had made an exit). The crankcase is fed through 3rd ports, pistons are deflector type and the exhaust dumps into a muffled chamber with an under-water outlet. There is no water pump… water pick-ups are in high pressure points on the front-sides of the two propeller blades. The lower unit gear ratio is 12:20. Overall, this motor was pretty much of a dismal failure on race courses but it’s relative rarity (sales weren’t very impressive and of those that were sold, most self-destructed) and distinctive looks make it popular among racing motor collectors.

The history of this particular motor is unknown but it was found in northern Wisconsin.

|

1929 Lockwood Model 92 BR Racing Chief (2)

|

2nd photo

|

Konig 250cc Opposed Twin

|

Konig 250cc Opposed Twin

This motor was built in 1968 by Harry Harden of Linden, Michigan using many parts (cylinders, heads, pistons and rods) from a 250cc 3rd port alternate firing twin. The crankcase was machined from a solid billet. It has three carburetors… two outboard on cylinder 3rd ports and a third on reeds feeding directly into the crankcase. A single large float bowl feeds the multiple carbs. A lightweight flywheel is used along with battery ignition timed by points on a movable stator plate. Fixed position expansion chambers are supported with springs. An early Konig stick tower and LU are used… the latter with a 16:20 gear ratio and water pick-up on the nose of the LU. The clamp brackets are modified Mercury aluminum forgings. The source of the crankshaft is unknown.

Harry said he won a lot of PRO 250 Hydro races with this motor and that was confirmed by Ed Thirlby. It was extremely competitive with the Konig FA motor on short courses. Only one was built like this and it was raced in 1968, ‘69 and ’70 before being rendered obsolete by the rotary valve Konig VA motor.

|

Konig 250cc Opposed Twin (2)

|

2nd photo

|

Konig 125cc Single

|

Konig 125cc Single:

This motor was the second of two built by Pete Hellsten for his son, Chris. The first was made in 1977 with parts from a 250cc alternate firing twin (FA). After failing the original motor’s crankcase and block, the second motor was built in 1978 with a new crankcase machined from a solid cube of aluminum. A single carburetor feeds a 3rd port + reeds in the cylinder block. Around 1980, the FA-based block was replaced with a Konig “M” cylinder (also with 3rd port + reeds). A lightweight flywheel is used with battery ignition timed with an electronic module. The motor exhausts into a sliding expansion chamber. A stick tower mounts a later model Konig LU with a 11:15 gear ratio. There is no water pump… the water pick-up is on the underside of the LU nose cone.

Chris Hellsten had pretty good luck with his “M” motors, winning the 1977 and 1980 Eastern Divisional Championships for 125 Hydro. This motor was used through 1984 and saw action in a lot of races. The motor was then sold to the late Tom Squicciarini who continued racing it into the 1990s. Being an unbalanced engine that was run at pretty high speeds, durability must have been a constant concern (as evidenced by the number of braze repairs on the cylinder block).

|

Konig 125cc Single

|

2nd photo

|

1954 Scott-Atwater Green Hornet Racer

|

1954 Scott-Atwater Green Hornet Racer:

This racing version of the 16 horsepower model 3945 service motor is the third and last iteration of a potential class B competitor from Scott-Atwater. Scott had initially offered a racing lower unit in their 1950 accessory catalog to enable their buyers to compete in class B with racing motors from Mercury and Champion (and later with Martin and Chris Craft). Hubbell was sourced to provide a streamlined lower unit sans water pump with a 13:19 ratio. The design was based on the Johnson KR so it has the same RH prop rotation along with the attendant cornering disadvantages . A compatible short tower mid-section was part of the package and served to lower the motor’s center of gravity. Prop wash and forward motion induced coolant flow into a water pick-up on the underside of the cavitation plate. The package was made for use on the new 16 horsepower model 509. While their overall motor design was well engineered with low-friction bearings throughout, reed valves, deflector pistons, short tower mid-section and other competitive features of that era, it was at best competitive with the Mercury KG-7H, but typically not quite as fast. Consequently, sales of the Green Hornet lower unit were quite limited and, as such, motors equipped with them are rare today. In 1954, Scott was introducing their new model 3945 motor and they had visions of sponsoring a factory racing program to support their new product. Unfortunately, the Mercury Mark 20H motor proved to have a considerable speed advantage over the Scott offering. A “last-ditch” effort was made by Scott to increase horsepower by outfitting a one-off prototype motor with a special intake manifold and dual carburetors but little improvement was seen. Thus, the intended factory racing program never got off the ground and the remaining Green Hornet lower units were disposed of through catalog sales, largely to “cottage racers”. While the Scott Green Hornet racer was an attractive looking motor, it had to be considered a dismal failure.

The history of this particular motor is unknown.

|

1954 Scott-Atwater Green Hornet (2)

|

2nd photo.

|

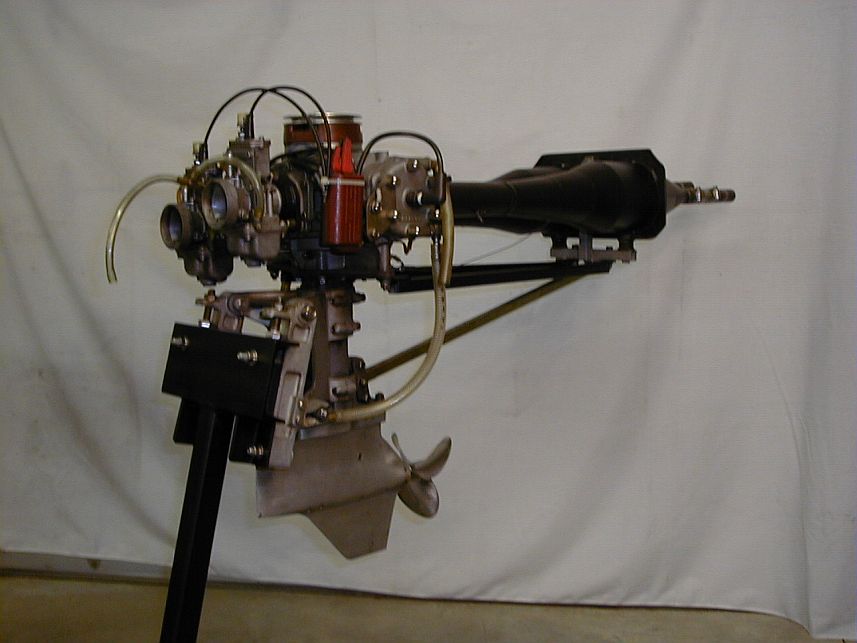

1996 Kawasaki 250 Racer

|

1996 “Kawasaki” 250 Racer:

This opposed twin PRO-Series alky motor was built by MSR (Mike Schmidt Racing) using parts from numerous sources. The loop-scavenged cylinders and pistons are from 125cc Kawasaki dirt bikes, the crank is Yamato, connecting rods are Yamaha and lower unit is a Yamato “hatchet” type with a 12:16 gear ratio. The twin carburetors are Mikuni sliding-plate type and pyramid reeds are typical snowmobile fare. Exhaust dumps into two sliding expansion chambers. There is no water pump… coolant flow is induced by forward motion with the water pick-up on the nose of the lower unit. Mike was one of, if not the first to use a 5-bladed prop in PRO-Series racing. Ignition is electronically-triggered and battery powered. The powerhead sits on a stick tower with a tee-type boat mount. Many of the remaining parts are fabricated or machined.

Despite its home-made origins, this motor is a real “looker” with much clearly evident attention to detail. It also is a proven winner as evidenced by its 1996 PRO-Series 250 Hydro National Championship with Mike at the helm.

|

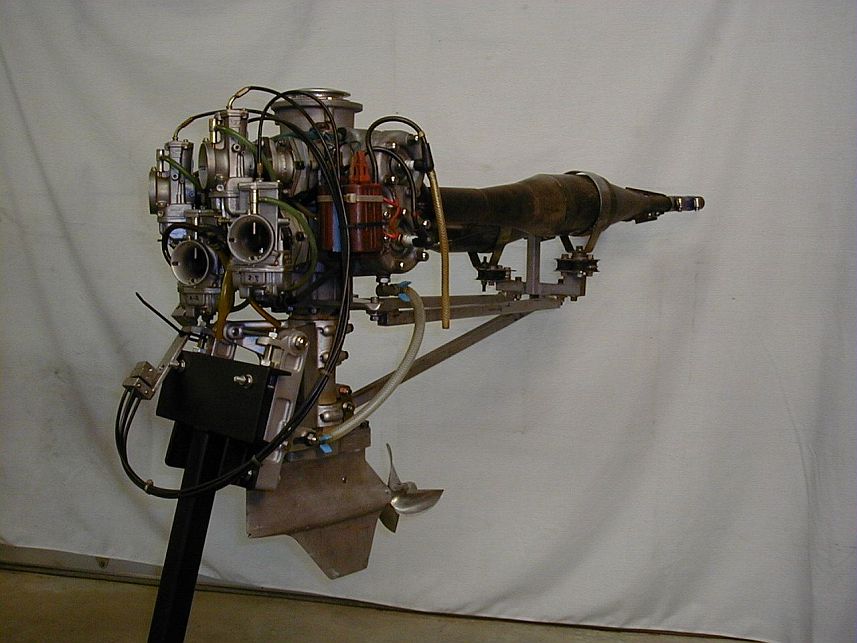

1996 Kawasaki 250 (2)

|

2nd photo

|

Chris-Craft K-X 10

|

This Chris-Craft "Grand Rapids Racer" was purchased in it's original, never run condition.

|

Yamato 250

|

This Yamato 250 race engine was originally owned and raced by Mike Krier.

|

Yamato 350

|

This Yamato 350 race engine was originally owned and raced by Mike Krier, who won many races and several championships with it.

|

1st Rossi 350 3-cylinder B Engine

|

I got the Rossi motor parts and was fortunate to find enough pieces to put it together (all except for the lower unit and ignition system, which I will have to buy separately). I have been conversing with Rex Hall about the motor and he asked what the serial number was on the back of the crankcase. I said I couldn't find one but I had heard that this motor was raced by the Thirlbys and that they may have won a couple of championship races with it... Rex said there should be two numbers stamped on the crankcase. I told him all I could find were two number ones stamped on either side of the crankcase split near the top. He then informed me that this undoubtedly is the first 350 motor ever built and it was Mr. Rossi's personal motor with which he won the national championship in 1997 at Cypress Gardens. Rossi obviously must have put it up for sale after that race and Ed Thirlby bought it. I visited Ed shortly after that time and saw it in his shop and asked him what the hell a Konig man was doing with a Rossi. He told me that he bought it mainly to find out why it was so fast. He said it has some new-fangled port that goes directly from the reeds to the combustion chamber but he wasn't sure how it worked. Little did we both know at that time is that this feature was the now widely popular "7th port" that all of the top motors are using. Suffice it to say that this pedigree is absolutely blowing my mind and that it is so ironic that I had seen this motor before. The other good news is that the motor is still runnable. Man, I am pumped!

Mark

|

1st Rossi 350 3-cylinder B Engine (2)

|

I just received confirmation from Rex Hall that the motor I have is indeed the one that was raced by Mr. Rossi (serial number 1), which won the 1997 World and European Championships. I had told Rex that the parts I received included some pistons and rods for use with 15mm wrist pins. Rex had thought all 350s were built exclusively with 16mm pins and wasn't sure what these smaller pins were from. But Mr. Rossi told him that the 15mm pins were correct for my motor because the 16mm pins did not become available until the start of the 1998 350 builds. Thus, the 15mm parts helped to confirm the pedigree of this motor. This story just keeps getting better!

Mark

|

Mike Krier's Championship 1987 Yamato 350 Pro Racing Motor

|

1987 Yamato 350cc PRO Racing Motor:

This motor was owned and raced by Mike Krier, a renowned racing runabout builder from Ollie, Iowa. It was used on a Krier-built runabout for a little over 10 years with unbelievable results… including 6 National Championships (with 4 in a row), 4 US Title Series Championships, 2 National High Points Championships and 2 competition speed records. Along the way, Mike did extensive development on the motor in the areas of improved carburetion (substituting Mikuni slider-type carbs for the original Yamato conventional throttle plate carbs), more aggressive exhaust port timing and re-tuning the exhaust system. His success led Yamato to adopt many of the same improvements in their subsequent racing motor designs.

The basic motor design is an opposed flat four-cylinder configuration with one Mikuni TMX-35 carburetor per cylinder. Pyramid reeds feed the methanol fuel mix through the crankcase as well as through “7th ports”. The generous total port flow area, flat top pistons, high compression ratio and loop-scavenged combustion process all contribute to the obvious stellar performance. Ignition is by Motoplat and exhaust is fed into two tuned expansion chambers (Yamato “high rpm” pipes). A Yamato tower was used with a Yamato “hatchet” type lower unit containing a 12:15 set of gears. There is no water pump… cooling water is forced through the system by forward motion of the motor. The water pick-up is on the underside of the gearcase nose cone.

Aside from being a real runner, this motor is just plain awesome looking… all you can see is carburetors when it is heading toward you. And it was always used in conjunction with an incredibly quick and great looking boat.

|

1987 Yamato 350cc PRO Racing Motor

1987 Yamato 250cc PRO Racing Motor

|

1987 Yamato 250cc Racer:

This is another Mike Krier motor that has had a very successful career running in the PRO 250 Runabout class. Before buying the motor, Mike had gained experience with the Yamato 250 motors as a factory test driver and was impressed enough to purchase one. The motor started out as a special build from the Yamato Technical Division #4 and was further developed (modified) by Mike to improve performance (e.g., by revising port timing, carburetor type, etc.). The basic motor is an opposed twin with pyramid reeds and 7th ports helping the engine to induct the methanol-oil mixture. Mikuni slider-type carburetors, large ports, flat top pistons, loop-scavenged combustion process and tuned expansion chamber exhaust all help generate an impressive level of performance. Ignition is by Motoplat. A Yamato tower mounts a Yamato “hatchet” type lower unit with 12:16 gears. There is no water pump… a water pick-up on the underside of the gearcase nose is used to force water through the cooling system.

|

1987 Yamato 250cc Pro Racing Motor (2)

2011 - 2012: New Additions to the Collection

1971 Konig FA

|

This PRO 250 class in-line twin is the second generation of the Konig FA motor design. It has been restored as last raced. The first generation was a loop-scavenged, piston port motor with a gear driven Bosch or SEM magneto, fixed-position expansion chambers and exhaust header pipes that were mounted on a curved surface. Both magnetos and exhaust header sealing were quite problematic. The second generation of this motor includes the following upgrades:

(1) Eliminating the magneto in favor of using battery ignition for improved ignition system reliability. (2) Supplementing the piston ports with reed valves into the

crankcase (2 petals per cylinder) to improve performance. (3) Incorporating sliding expansion chambers to enhance

performance in the corners as well as in the straight-away. (4) Making the header pipe sealing surface flat to improve sealing. The motor originally came with a two-into-one header pipe and single expansion chamber but some previous owner opted to refit it with after-market header pipes and two expansion chambers to improve upon the exhaust system tuning. These pipes and exhaust headers

were likely produced by Aircone, Inc. of Henderson, Nevada... their restoration was done by Steve Litzell of Marietta, Georgia. The only other significant motor modification was to streamline the carburetor inlets by welding on entry cones. The motor uses two Bing carburetors with rotary throttles and remote-mounted float bowls. The fuel is a methanol-castor oil mix. Crankcase pressure is used to push the fuel into the carburetors from a remote tank in the boat. The lower unit is an early Konig design with no water pump and a 1:1 gear ratio. Forward motion of the motor through the water is used to push water through the cooling system... failure to get the boat quickly on plane risks over-heating the motor. The tower is a standard Konig fabricated steel design with an integral water supply

tube and steering bar mount. The boat mounting system is a

standard Konig "T" bar design. The ignition system is simple... ignition points actuated by a cam on the flywheel and two Prufrex ignition coils. It was designed for use with a battery mounted in the boat. Most of the racing history on this motor is unknown but the last owner/driver of record was the late Tom Squicciarini of Big Rapids,

Michigan.

|

1964 Mercury 350 C-Service Racer

|

This is a 2-cylinder Merc powerhead with 2 7/8' bores... the compression is awesome for an alternate firing twin. It has a stick tower with Konig mounts and a C-Service legal Evinrude Speeditwin antique lower unit sans water pump. It was raced by Dale Robertson with about 35% nitromethane in the fuel and it threw a flame about 3 feet out of the port side of the engine. It has a 3-blade prop that was purchased from the Seebold family and it definitely was a front-of-the-pack motor in its day. Parts include a British Anzani flywheel, original Merc 350 carburetor and stator plate (points and condensers) with after-market coils, a battery in the boat and an adapter to provide a mount for a Mercury-style steering bar.

|

1964 Mercury 350 C-Service Racer (2)

|

|