|

|

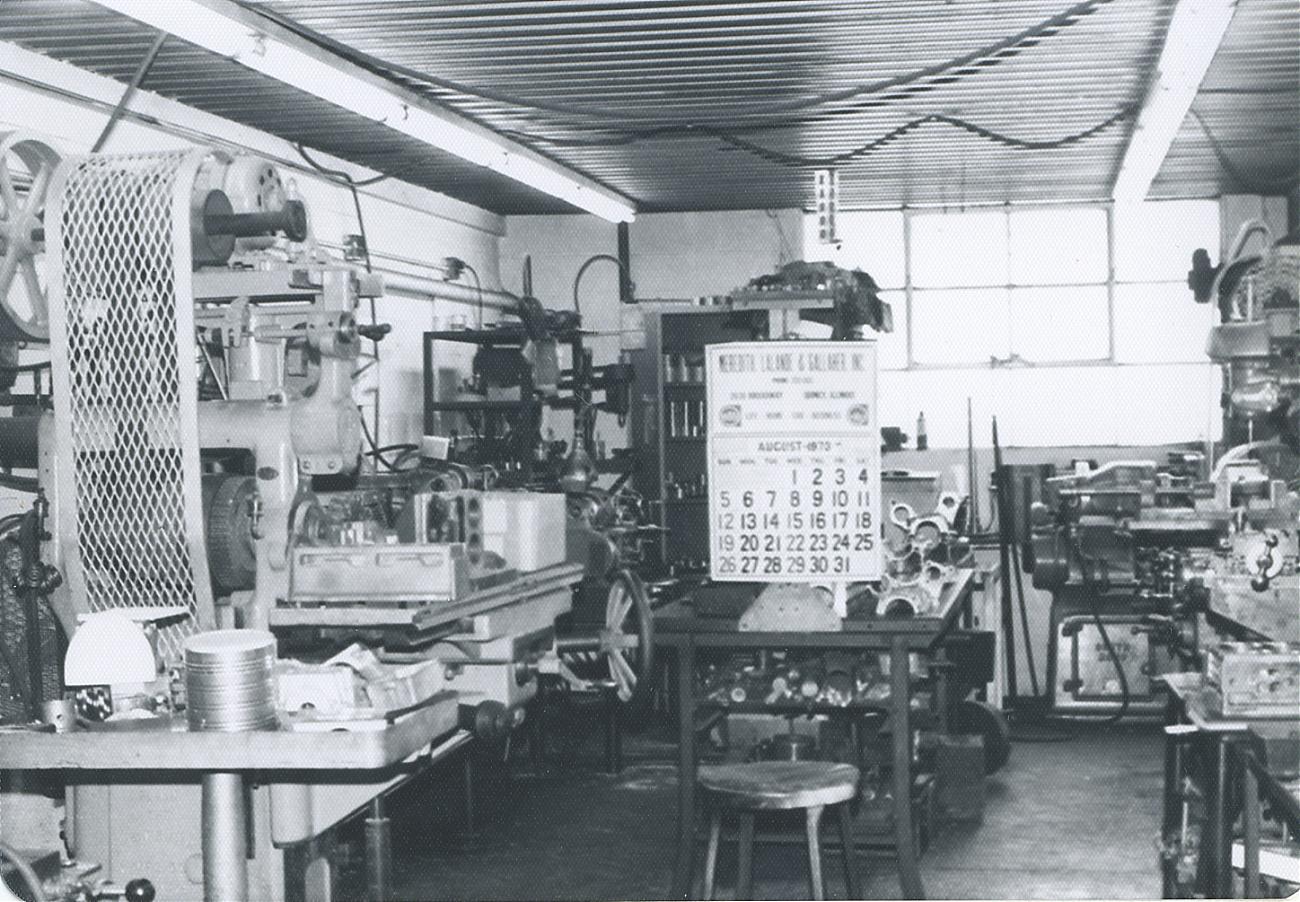

Shop Photo 1

|

The 1st picture is of the northeast section of the shop, looking east. This is the area where the cylinder blocks and crank cases were exterior machined for further production. In the extreme NE corner of this picture is where the Quincy pistons were machined and produced.

|

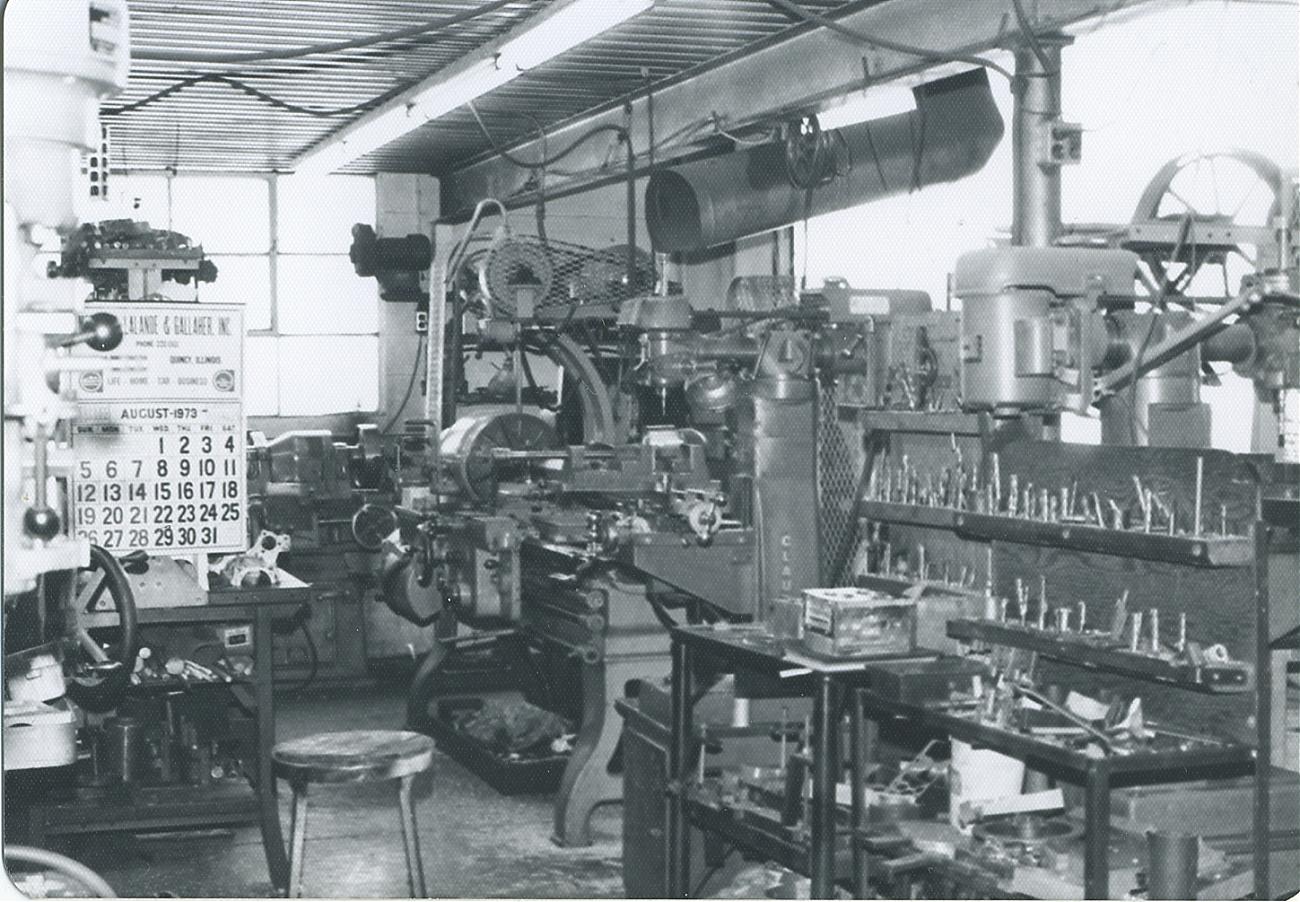

Shop Photo 2

|

The 2nd picture is also of the machine shop area (east and somewhat south of the north end of the building). This is where we finish machined the crankshafts that we made and also the cylinder heads, cranking plates and other parts that required a larger lathe for the Looper finish production.

Special note: the Clausing end mill in the right side foreground is the very one that the world famous Gene East used to hand port the majority of the Quincy Loopers that were manufactured.

|

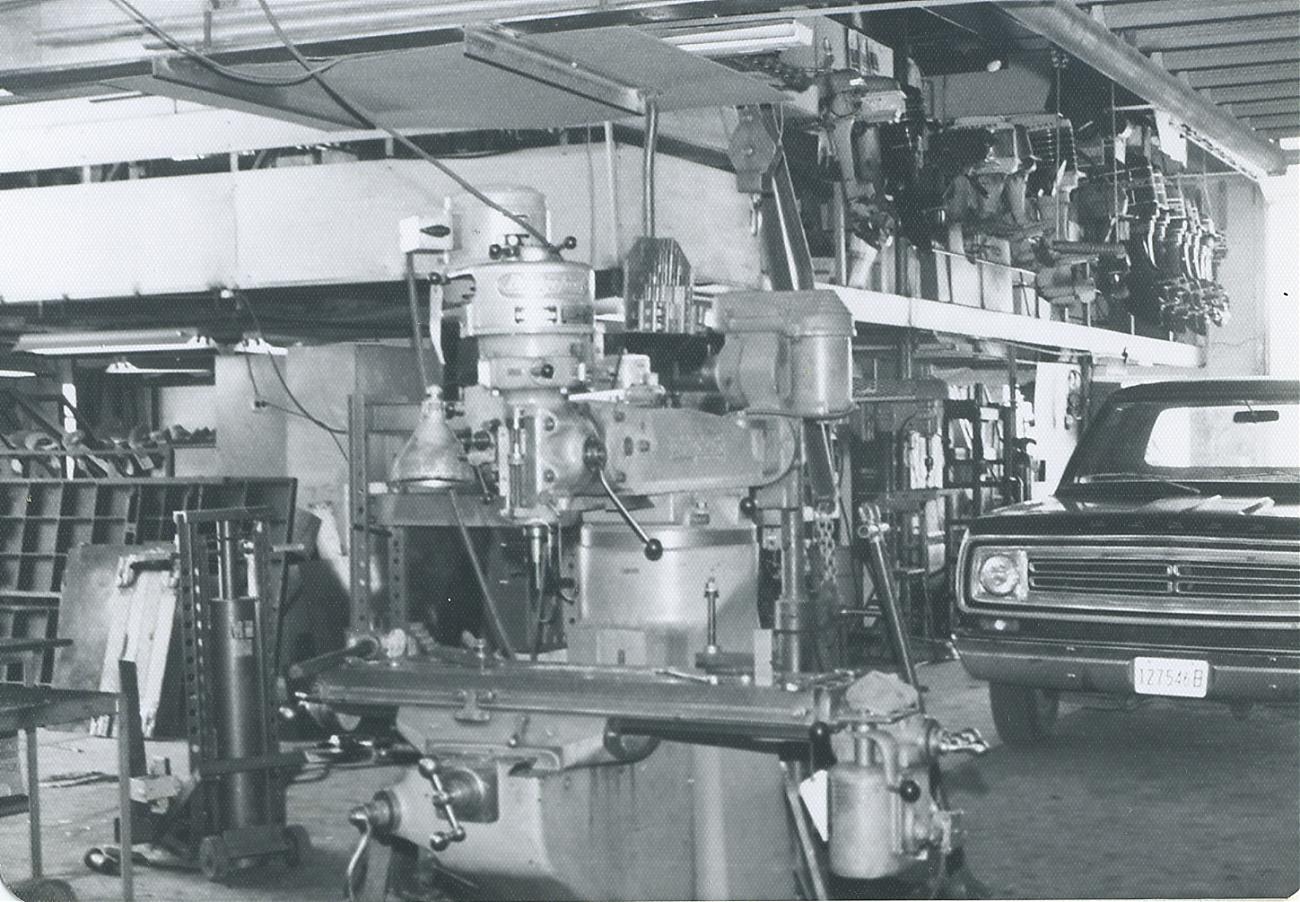

Shop Photo 3

|

The 3rd picture is looking towards the southeast. This bridgeport was used for porting many factory Merc blocks that we modified and some machine finish work on the Loopers. In the background you will see the Dodge shop truck and on the upper rack, many customer outboards in for repair plus some new Mercury engines for sale. You will notice that the engines are on an upper level - the upper level was where we worked on outboards, both pleasure and racing, and where we finish assembled the production racing engines. (More pictures of that area to be posted later.)

|

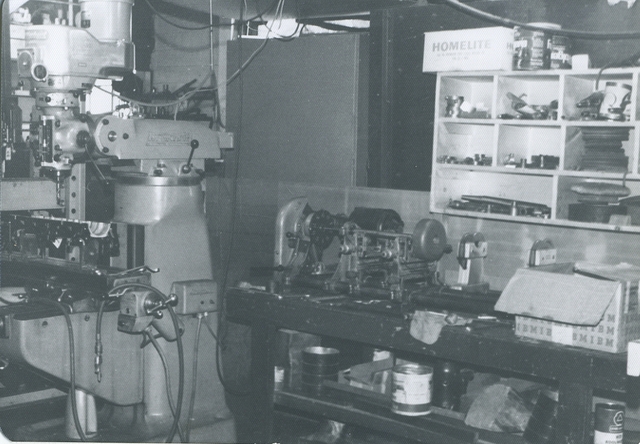

Shop Photo 4

|

The 4th picture is of the drill press machining room/ drawing room. This is where most of the drilling and tapping of the production race engines took place and also where my father had his large drafting table (not seen in the picture). This area was kept as clean as a surgical center because some of the most critical and delicate drilling & tapping work occurred here.

|

Shop Photo 5

|

The 5th picture is one of my favorites - the Looper parts inventory. This was also kept in the drill press machining room. How many of us would love to reach back into this picture and snatch brand new, freshly machined parts for our Loopers? Wow!

|

Shop Photo 6

|

The 6th picture of this series is of the pleasure boat propeller repair area and also where we forged Quincy racing propellers. This is where Gene East, Frank Volker and Al Herman performed magic for both stock and racing outboard uses.

Special note: Look above the light fixture over the work bench and towards the back of the shop. You will see an area we called the "Back Deck." That is where the majority of covert, experimental "X" factory secret blocks were kept hidden. The only way to reach that area was to lower the steps with an electric wench -- only certain shop employees were allowed up there. Gene can tell you how off limits that deck was.

|

Shop Photo 7

|

The 7th picture is mid shop, looking northeast at the larger bridgeport endmill that was used primarily for larger porting and machining projects & 6 cylinder Loopers. To the south of the bridgeport is the electrostatic crankshaft balancer. Many national championship engine crankshafts were balanced on this machine. We also used this machine to balance prop shafts with racing propellers on them.

|

Shop Photo 8

|

The 8th picture is of the boring room. This is where most of the Looper production engines were final bored. The final honing was done upstairs prior to final assembly.

|

Shop Photo 9

|

The 9th picture is from the central far eastern part of the shop and is of the belt sanders and the propeller work area. Note: Quincy Welding employee, Gene East, spent a lot of time working in that area on props and grinding various projects.

|

Shop Photo 10

|

The 10th picture is looking south to north, from the main State street vehicle entrance to the shop. My dad, O F Christner, is leaning on the shop truck, talking to his friend, Fred, that ran a business across the street. If you look towards the back, you can see a number of research Loopers on the back deck. As I discussed in the previous post on the shop, that area was off limits to almost everyone and could only be reached by a set of steps that had to be lowered (you can see them in the picture).

|

Shop Photo 11

|

The 11th picture is looking towards the northeast part of the shop at the big southbend lathe and the machine we used to finish the Looper exhaust elbows. Notice the boxes on the back deck at the top of the photo? Those boxes contained many research blocks from the Mercury factory and some from other companies that we were doing covert R&D research for.

|

Shop Photo 12

|

The last picture is also looking towards the northwest at the large bridgeport that was used for crankcase boring of the Loopers and the machine to the right of it was used for finishing the Looper blocks externally before the crankcases were finish bored.

Hope you enjoyed this trip back in time.

|

|

|